Introduction

Cable trenches are vital for protecting electrical and communication systems. They safeguard cables from external damage and ensure long-term functionality. Choosing the right type of cable trench is essential for both safety and efficiency. In this article, we will explore the different types of cable trenches, focusing on the advantages of FRP Cable Trenches and why they are becoming a preferred choice for modern infrastructure projects.

Understanding Cable Trenches

Definition of Cable Trenches

Cable trenches are specifically designed for the underground installation of cables. These trenches provide a secure and protected route for electrical and communication cables to run beneath the ground, shielding them from external impacts, environmental conditions, and potential damage during installation and maintenance.

Without a properly constructed trench, cables would be exposed to risks such as physical impact, weather-related damage, or accidental cuts. By creating an underground pathway, trenching ensures the longevity and safety of the cables while also reducing the likelihood of costly repairs.

Historical Context of Cable Trenches

Historically, cable trenches were simple ditches dug by hand or with basic machinery. Early versions of these trenches were often shallow and prone to environmental wear. Over time, as the demands for infrastructure grew, trenching methods evolved to accommodate the more complex needs of modern utility systems.

Materials such as concrete, metal, and fiberglass have been integrated into trenching solutions to improve durability and resistance. Today, with the advancement of materials like FRP (Fiberglass Reinforced Plastic), cable trenches are more durable, efficient, and sustainable.

Key Factors in Choosing a Cable Trench

When selecting a cable trench, there are several critical factors to consider:

● Trench Depth and Width: The trench needs to be deep enough to protect the cables from environmental hazards like freezing temperatures, water intrusion, or mechanical damage. The width must also accommodate multiple cables and allow for easy maintenance.

● Environmental Conditions: The soil type, groundwater levels, and environmental factors will impact trench design. For example, areas prone to heavy rain might require additional drainage features in the trench.

● Material Durability: Depending on the location, materials such as concrete, metal, and FRP may be used. FRP Cable Trenches are particularly favored for their high resistance to chemicals, corrosion, and moisture.

Types of Cable Trenches

Traditional Cable Trenches

Traditional cable trenches are often made from materials like concrete or compacted soil. These trenches are straightforward to create and offer reliable protection for cables, but they have several limitations. Concrete trenches, for instance, can crack over time, while soil-based trenches may suffer from erosion or lack of proper drainage.

Pros:

● Widely available and easy to install.

● Provides basic protection against physical damage.

Cons:

● Susceptible to cracking or erosion.

● Require more maintenance over time.

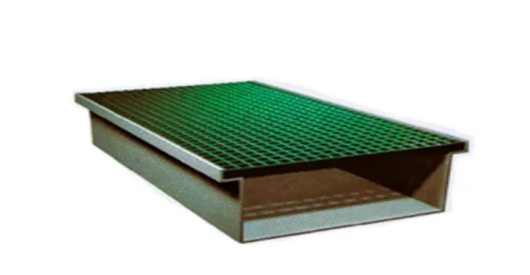

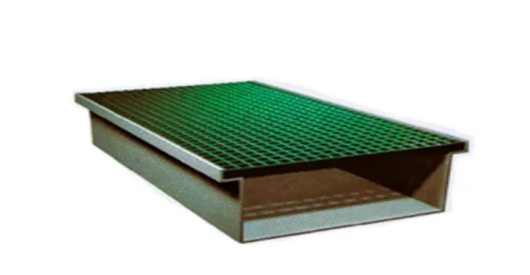

FRP Cable Trench

FRP Cable Trenches are designed using fiberglass-reinforced plastic, which offers superior strength, corrosion resistance, and durability. This makes FRP Cable Trenches ideal for areas that are exposed to extreme weather conditions or corrosive environments like chemical plants, coastal areas, or sewage systems.

Advantages of FRP Cable Trenches:

● Durability: Highly resistant to corrosion, making them a great option for industries exposed to chemicals or saltwater.

● Lightweight: Easier to handle and install compared to concrete or metal options.

● Maintenance-Free: Once installed, they require very little upkeep, leading to long-term cost savings.

Concrete Cable Trenches

Concrete trenches are a traditional choice for many types of cable installations. These trenches provide robust protection against external forces, and their strength ensures the safety of cables in high-traffic areas.

Pros:

● Strong, durable, and long-lasting.

● Suitable for heavy-duty environments.

Cons:

● Heavy and difficult to install.

● Prone to cracking if not properly maintained.

Trenchless Cable Installation

Trenchless cable installation is a modern method that involves laying cables without digging a traditional trench. Instead, equipment such as directional drills or horizontal directional drilling (HDD) creates a pathway for the cables underground. This technique is often used in urban areas to minimize disruption to roads and buildings.

Benefits:

● Minimal disruption to the surrounding environment.

● Faster installation with less digging.

Limitations:

● More expensive than traditional trenching methods.

● Not suitable for all types of soil or cable configurations.

FRP Cable Trench: A Modern Solution for Cable Management

What is FRP Cable Trench?

An FRP Cable Trench is a type of cable trench system made from fiberglass-reinforced plastic. It consists of panels or pre-formed sections that interlock to create a secure and reliable pathway for cables. The material itself is lightweight, durable, and resistant to environmental stressors such as moisture, chemicals, and temperature fluctuations.

Benefits of FRP Cable Trench

The FRP Cable Trench offers a range of benefits:

● Corrosion Resistance: FRP is resistant to corrosion from chemicals and water, making it ideal for industries like telecommunications, energy, and utilities.

● Durability: With high resistance to UV rays and extreme temperatures, FRP Cable Trenches provide long-lasting performance even in challenging conditions.

● Ease of Installation: The lightweight nature of FRP makes installation faster and more cost-effective than traditional materials like concrete or steel.

Comparing FRP Cable Trench to Traditional Options

When compared to concrete or metal trenches, FRP Cable Trenches have several advantages:

● Cost-Effectiveness: Although the initial installation cost might be slightly higher, FRP Cable Trenches require much less maintenance, providing long-term savings.

● Longevity: Traditional trenches made from concrete or steel are prone to cracking or corrosion over time. FRP Cable Trenches, on the other hand, are designed to withstand harsh conditions for many years without deteriorating.

Cost Comparison Table:

Material | Initial Cost | Maintenance Cost | Lifespan |

Concrete Trenches | Moderate | High (cracking) | 10-20 years |

Metal Trenches | High | Moderate (corrosion) | 15-30 years |

FRP Trenches | High | Low (minimal maintenance) | 30+ years |

Applications of FRP Cable Trench

FRP Cable Trenches are commonly used in various industries, including:

● Telecommunications: To protect fiber optic cables and communication lines.

● Electrical Infrastructure: Providing pathways for power cables in both urban and industrial environments.

● Utilities and Oil & Gas: Ensuring the safe installation of cables in areas that are exposed to extreme environmental conditions.

Installation Process of FRP Cable Trenches

Site Preparation for FRP Cable Trenches

Proper site preparation is essential for installing FRP Cable Trenches. This includes clearing the area of debris, ensuring proper drainage, and determining the trench's depth and width based on cable specifications. It’s important to work with experienced professionals to ensure the trench is aligned with industry standards.

Steps in Installing FRP Cable Trenches

The installation process generally involves:

1. Excavating the trench: Digging to the appropriate depth and width.

2. Placing the foundation: Installing a base layer to support the trench.

3. Assembling the panels: Interlocking the FRP panels together.

4. Cable placement: Laying the cables inside the trench and securing them.

Safety Considerations in FRP Trenching

Safety is paramount during the installation of FRP Cable Trenches. It is important to ensure that workers wear proper personal protective equipment (PPE) such as gloves and helmets. Additionally, the trench should be reinforced to avoid any potential collapse during installation or future maintenance.

Cost Considerations for FRP Cable Trenches

Comparing Costs: FRP Cable Trench vs Traditional Trenches

The cost of installing FRP Cable Trenches can be higher initially than traditional concrete or metal trenches. However, considering the longevity, ease of installation, and minimal maintenance, FRP Cable Trenches offer a better value in the long term.

Cost Comparison Table:

Material | Initial Cost | Maintenance Cost | Lifespan |

Concrete Trenches | Moderate | High (cracking) | 10-20 years |

Metal Trenches | High | Moderate (corrosion) | 15-30 years |

FRP Trenches | High | Low (minimal maintenance) | 30+ years |

Long-Term Savings with FRP Cable Trenches

While the upfront cost of FRP Cable Trenches may seem high, their resistance to corrosion and the lack of ongoing maintenance costs make them a wise investment. Over time, businesses save money on repairs, replacements, and labor associated with traditional trenching materials.

Conclusion

Choosing the right type of cable trench is essential for the long-term protection and efficiency of your cable installation. FRP Cable Trenches stand out as a modern solution, offering exceptional durability, ease of installation, and low maintenance. While traditional options like concrete and metal trenches have their place, FRP Cable Trenches provide superior performance, especially in challenging environments. For future infrastructure projects, FRP Cable Trenches should be considered a reliable and cost-effective choice. Avatar Composite Co., Ltd. is a leading manufacturer of high-quality FRP Cable Trenches, ensuring that your cable management needs are met with the best products available.

Comment: For businesses considering a cable trenching solution, FRP Cable Trenches offer long-term benefits that outweigh the initial investment. Their durability and low-maintenance properties, provided by manufacturers like Avatar Composite Co., Ltd., make them a superior choice for modern cable management needs.

FAQ

Q: What is a cable trench?

A: A cable trench is an underground pathway designed to protect and house electrical and communication cables, preventing damage from external elements.

Q: What is an FRP Cable Trench?

A: An FRP Cable Trench is made from fiberglass-reinforced plastic, providing excellent durability, corrosion resistance, and ease of installation, making it ideal for harsh environments.

Q: What are the advantages of using an FRP Cable Trench over traditional materials?

A: FRP Cable Trenches are lightweight, corrosion-resistant, and require minimal maintenance, offering a longer lifespan compared to concrete or metal trenches.

Q: How do you install an FRP Cable Trench?

A: Installation of an FRP Cable Trench involves excavating the trench, laying a foundation, assembling the panels, and then securing the cables within the trench.